Here goes a piece of advice for product developers how to avoid fat marks on paper marketing banderoles and leaflets.

When fat marks appear?

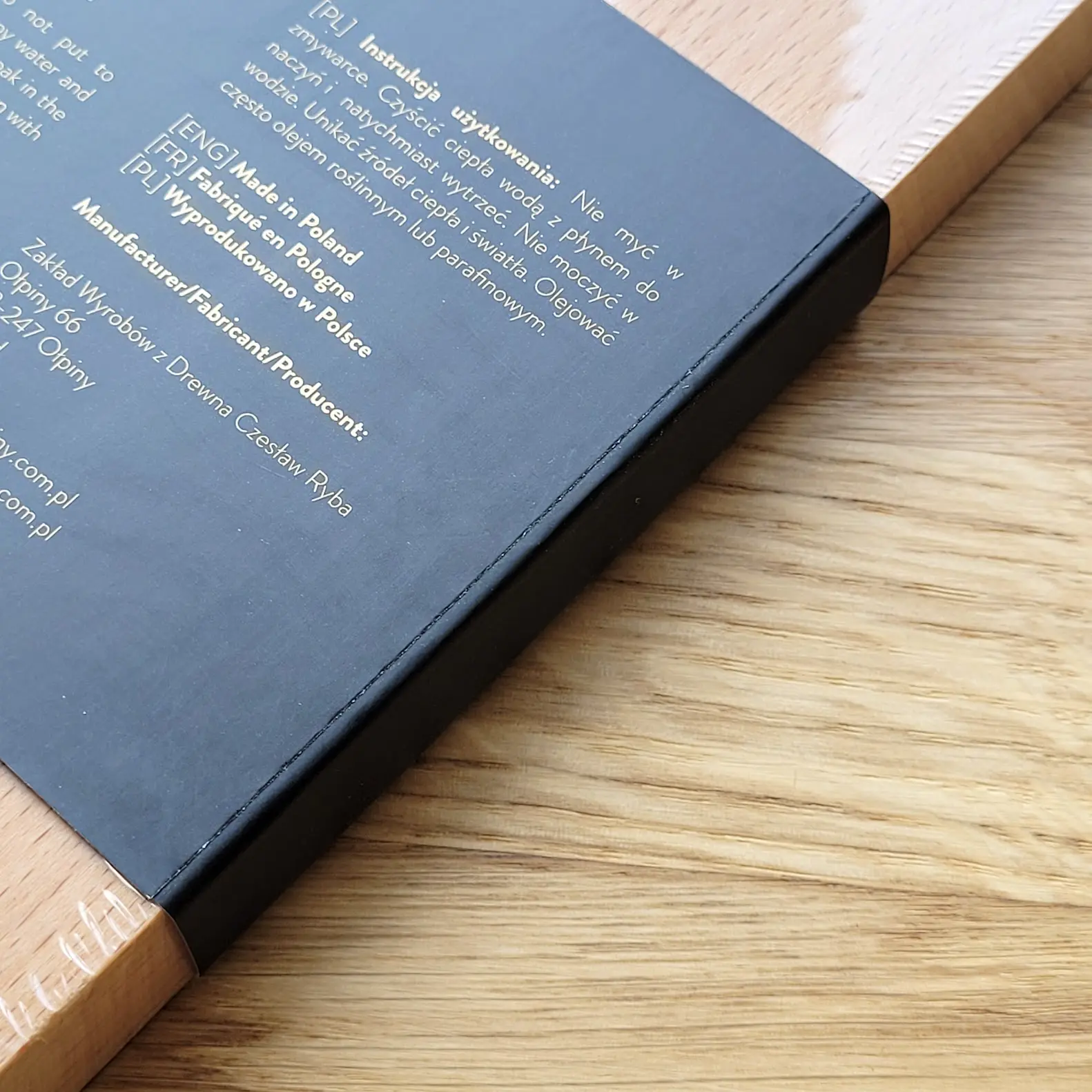

Fat marks may appear if an oiled wooden cutting board is placed directly on uncoated paper.

This can happen even when the board feels dry on the surface.

Solution 1: Leave board raw

This is the most economical option. You may instruct your customers to oil the board with paraffin oil before first use. This approach not only prevents fat marks on paper surfaces during packaging and storage, but also increases customer engagement with the product.

Solution 2: Use shrinkwrapp flm to separate banderole box or leaflet

The oiled wooden board is wrapped in shrink wrap foil, which creates a barrier between the board and the paper packaging. This prevents oil from migrating into the paper while allowing the board to remain pre-oiled and ready for use. This solution protects the packaging and maintains the product’s finished appearance.

Solution 3: Use hardwax

The board is finished with hardwax oil, which creates a protective layer that reduces the risk of oil migration into paper packaging. This solution is especially recommended for oak boards. Hardwax oil also provides additional surface protection and helps limit raised wood fibers. Many B2C customers consider raised grain a defect, without fully understanding that it is a natural characteristic of solid wood.

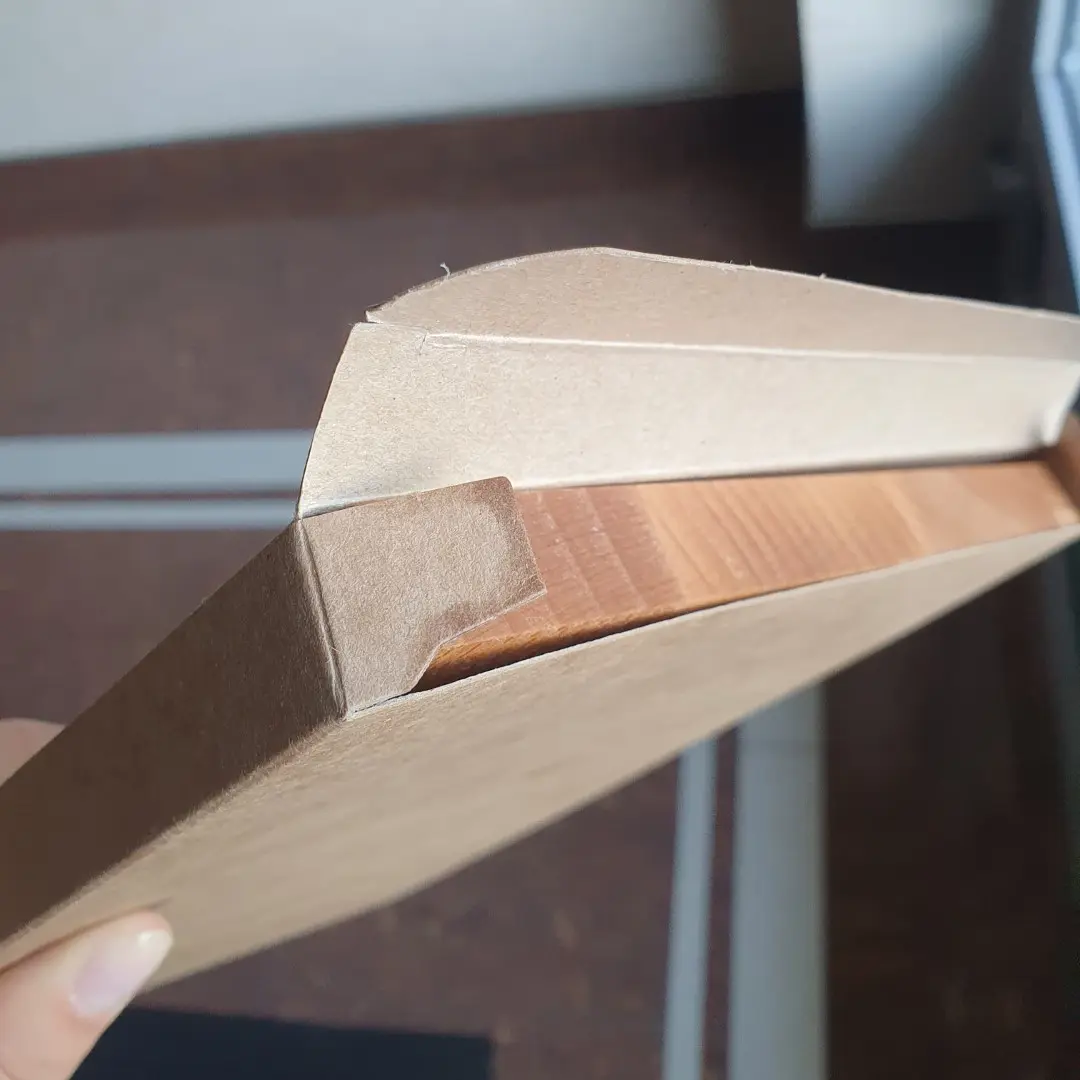

Oil stains on kraft cardboard packaging

The cardboard absorbs oil from unpacked products without protective foil.

This effect does not occur with raw products treated with hard wax or lacquer.

Kraft cardboard foil-lined inside

The inner foil lining protects the cardboard from absorbing vegetable or paraffin oil.

How to avoid olied marks on paper packaging?