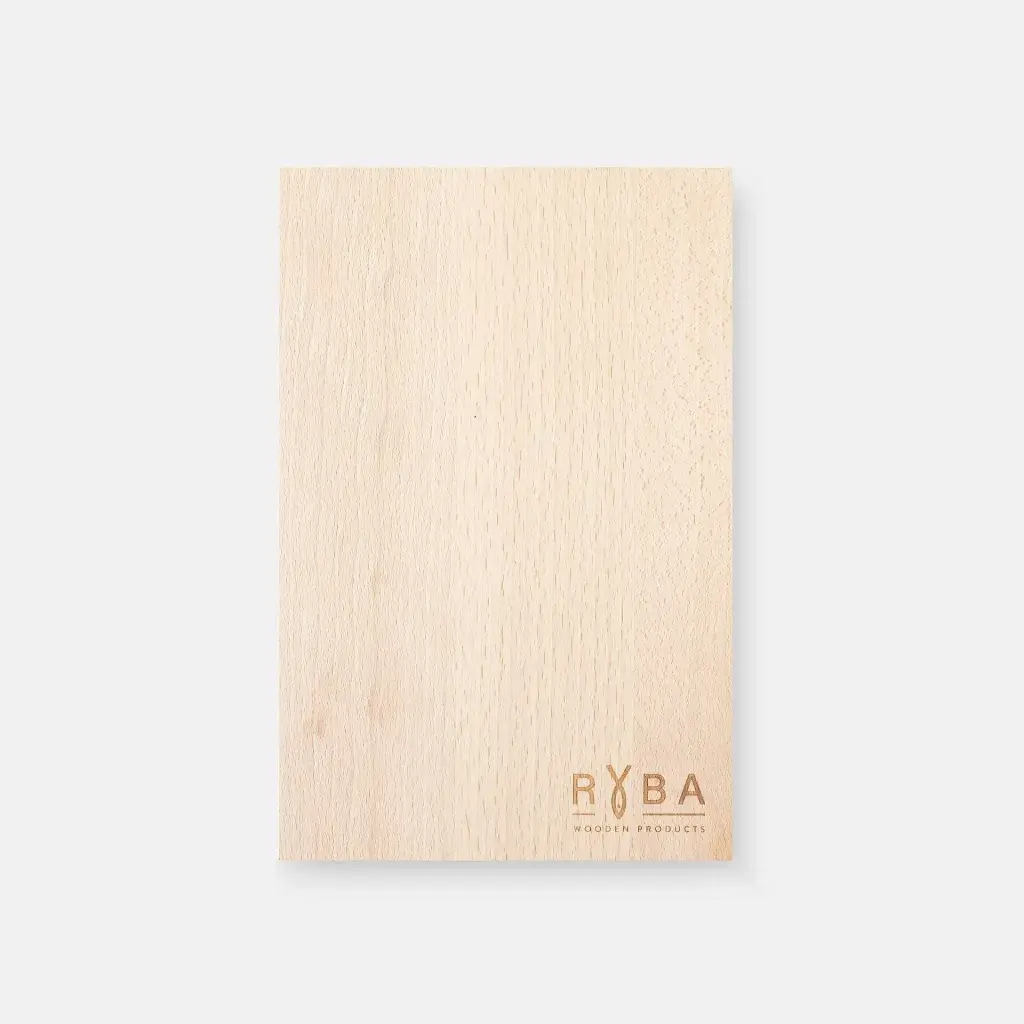

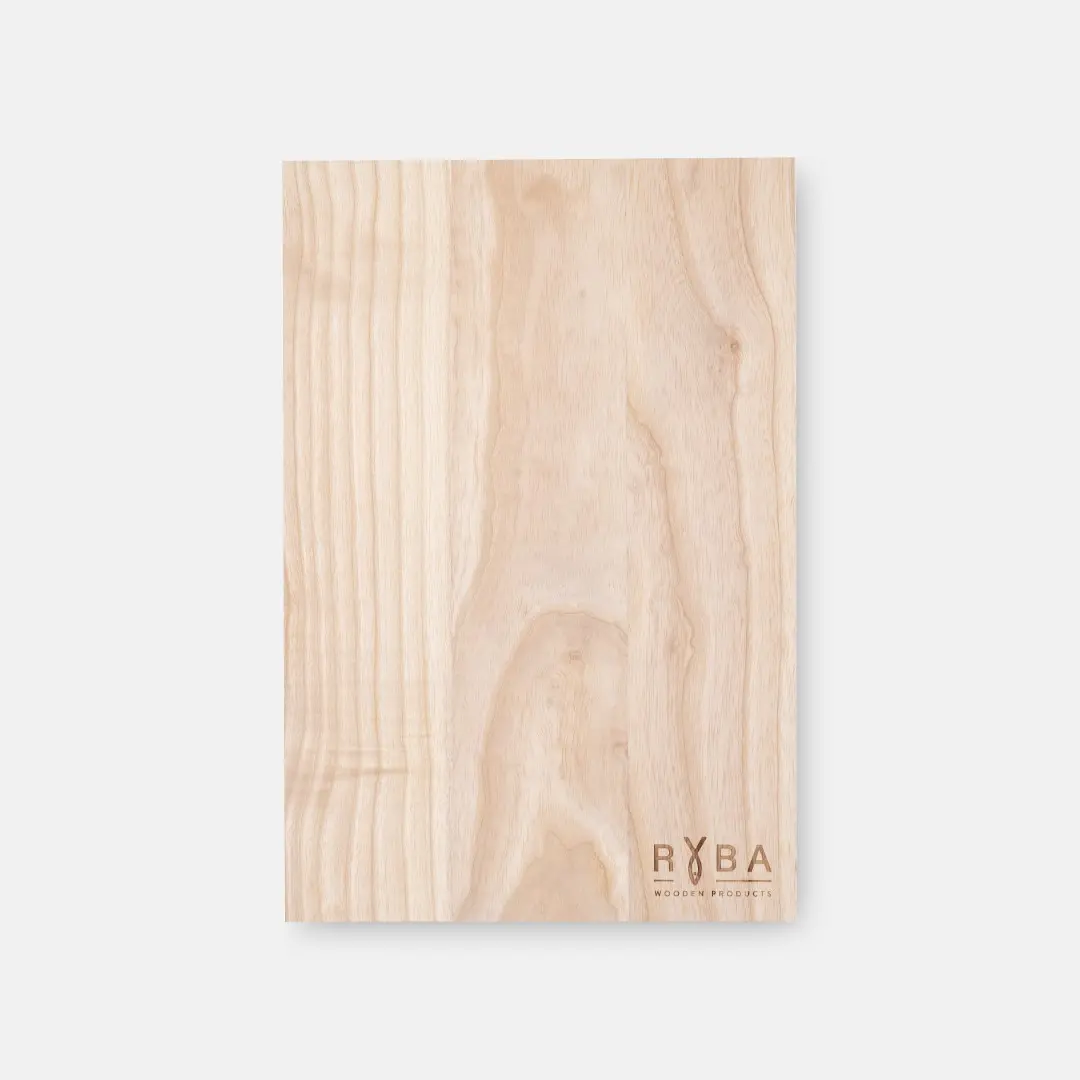

Beech

(Fagus sylvatica L.)

Beech wood is hard and durable. It has a uniform structure without a distinct grain pattern.

Beech is less resistant to water than oak or ash.

Differences in color are not a defect in the wood. The wood is glued from slats, and each slat may come from the center of the log. (beech core wood).

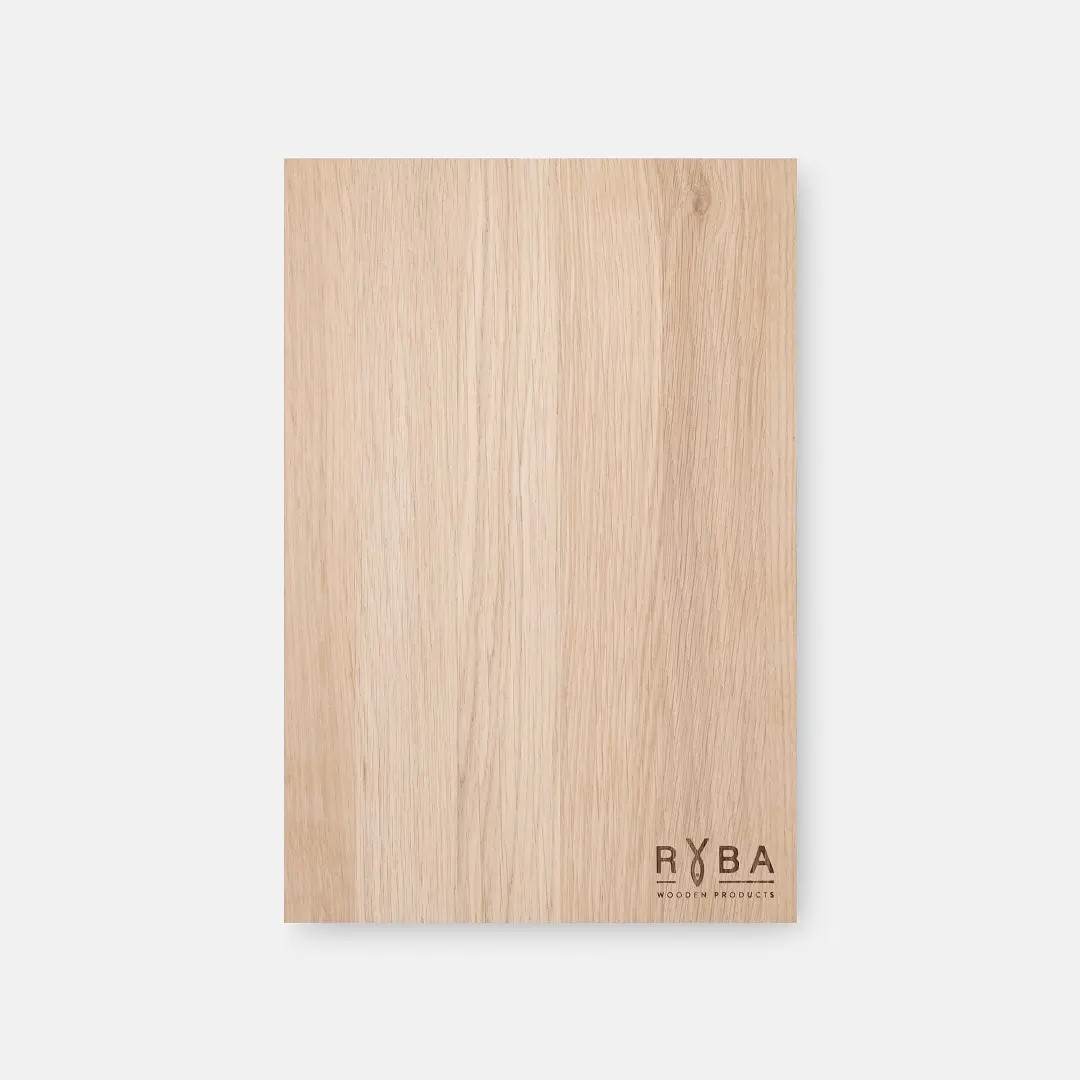

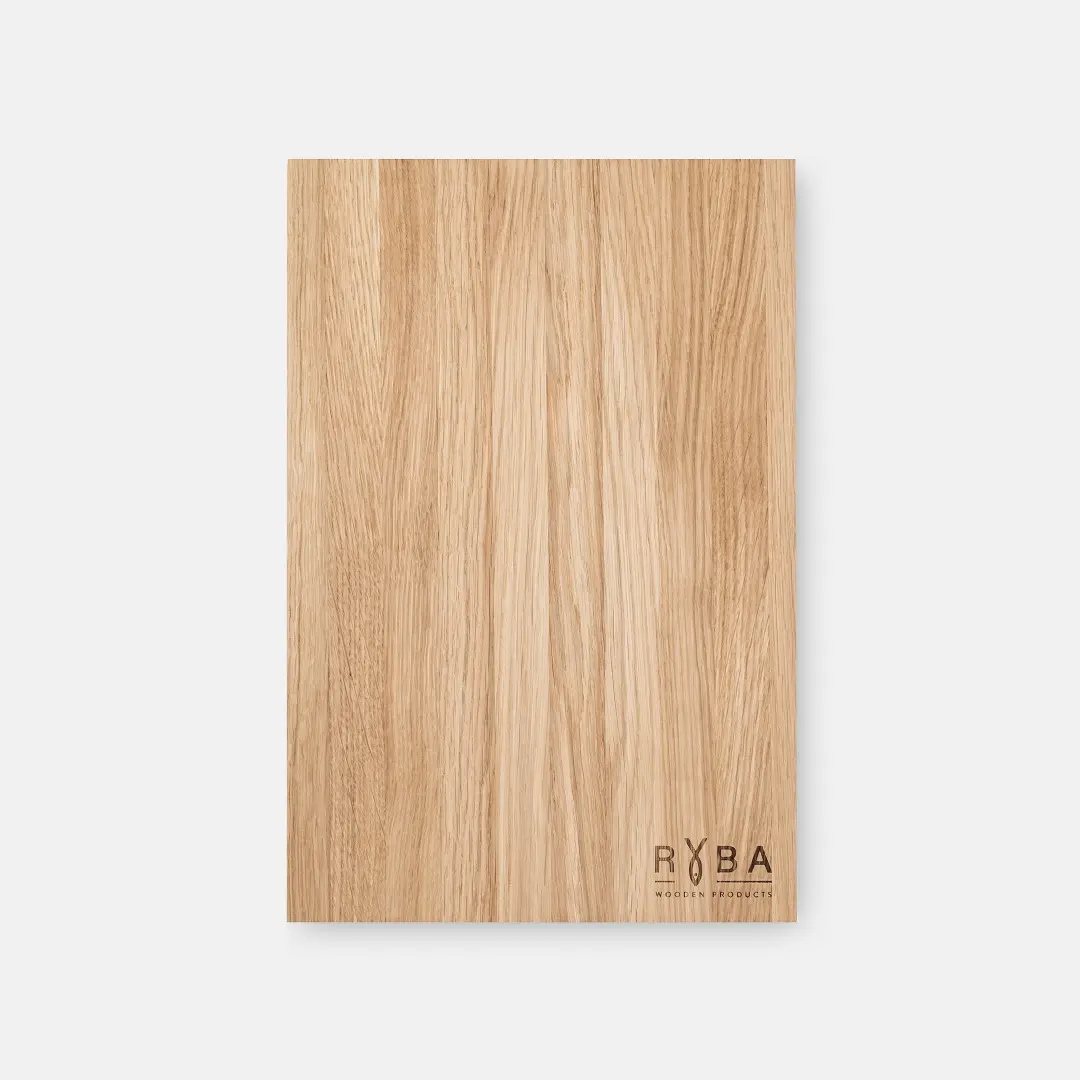

Oak

(Quercus robur L.)

Oak wood is hard, very durable, and resistant to mechanical damage. It is characterized by a distinct grain pattern and naturally high moisture resistance compared to beech.

We consider oak sapwood to be a valuable material. When gluing boards, we match elements with sapwood in such a way that they create a consistent, natural flame effect in the wood.. (more about what sapwood in oak...)

Oak board - rough after first contact with water. The first contact of oak wood with water may cause the surface to become rough. This effect is normal and disappears after a few washes. video...

Dark discoloration on oak wood. Oak wood can react with certain metals and change color (salad cutter, meat grinder knife).

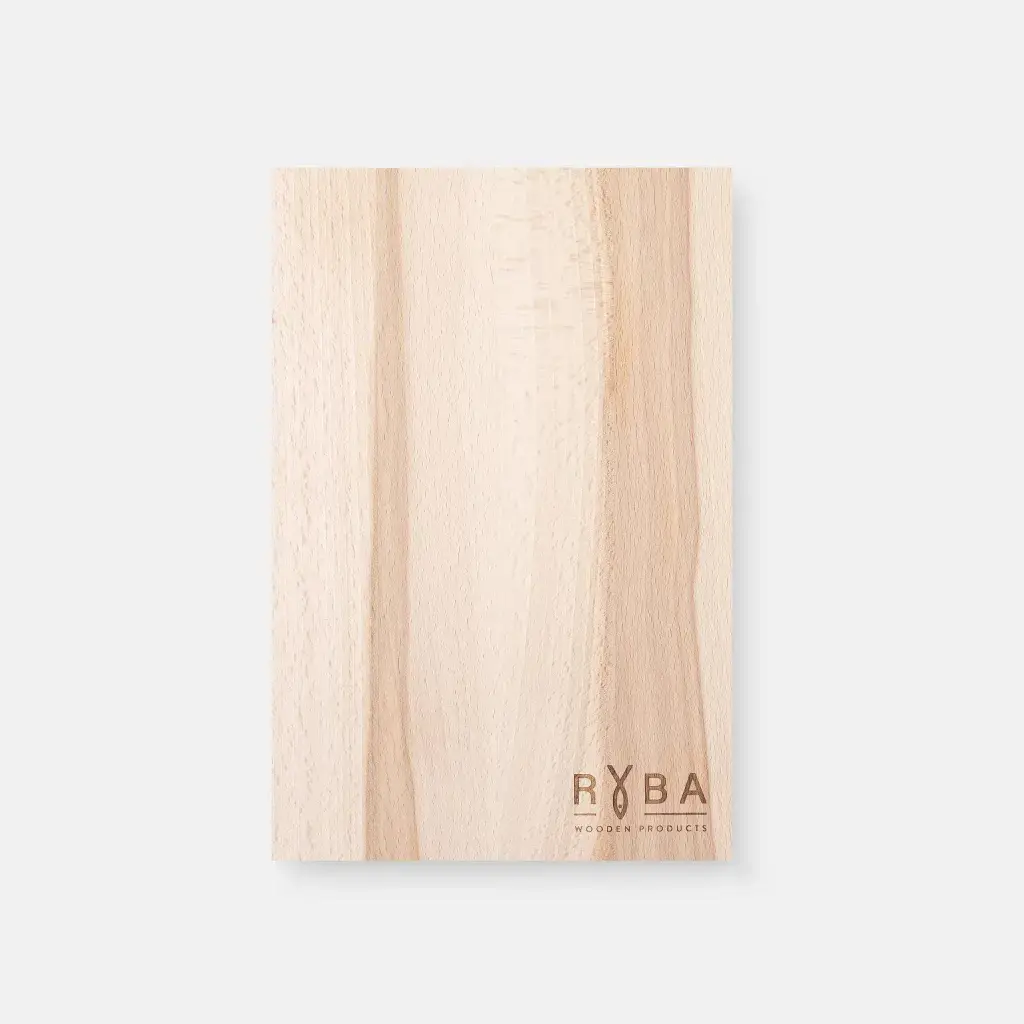

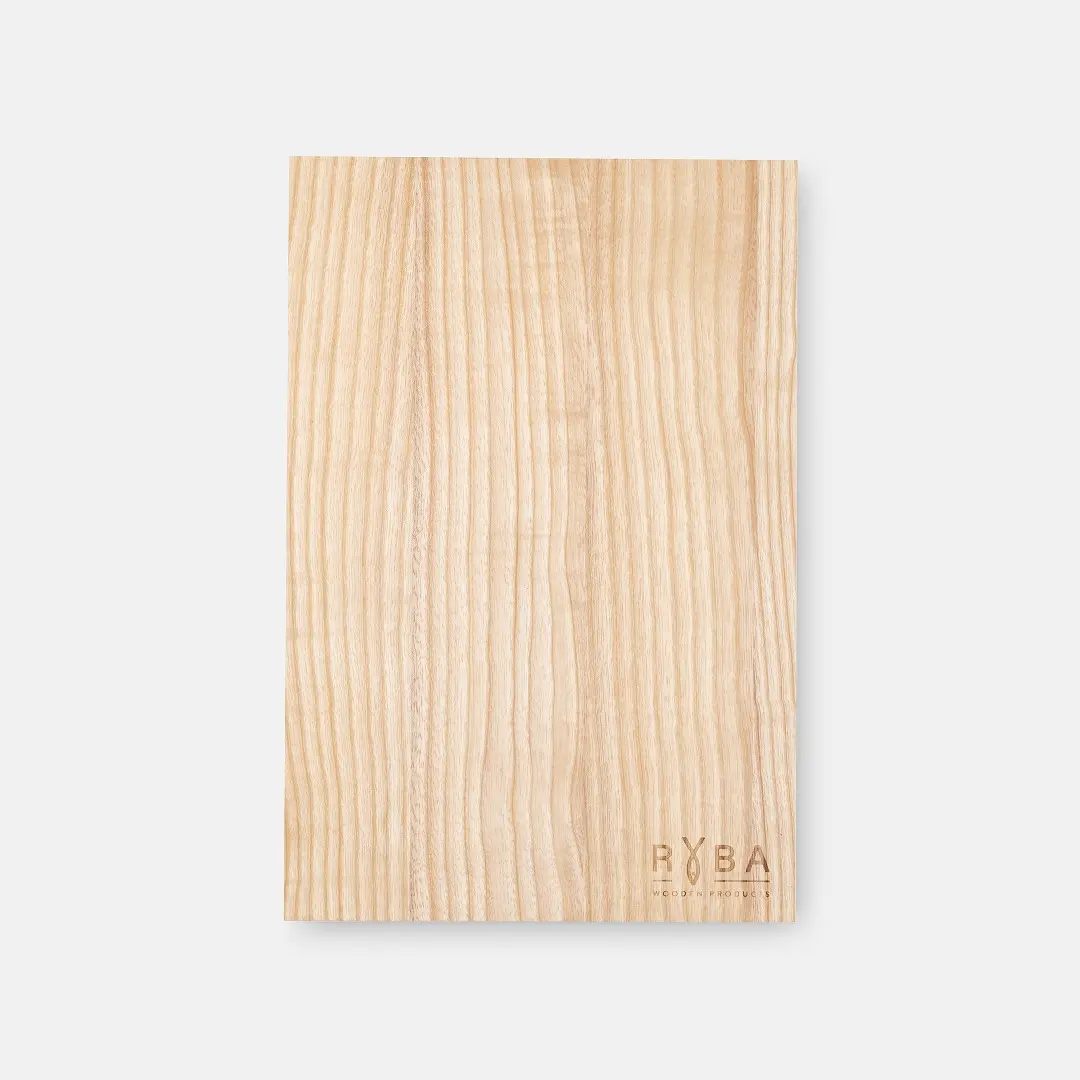

Ash

(

Fraxinus

)

Ash wood is hard, resilient, and very durable, yet lighter than oak. It is characterized by a distinct, dynamic grain pattern and a light, natural color. Compared to oak, ash is slightly less resistant to moisture, but it is perfect for indoor applications such as cutting boards and kitchen accessories.

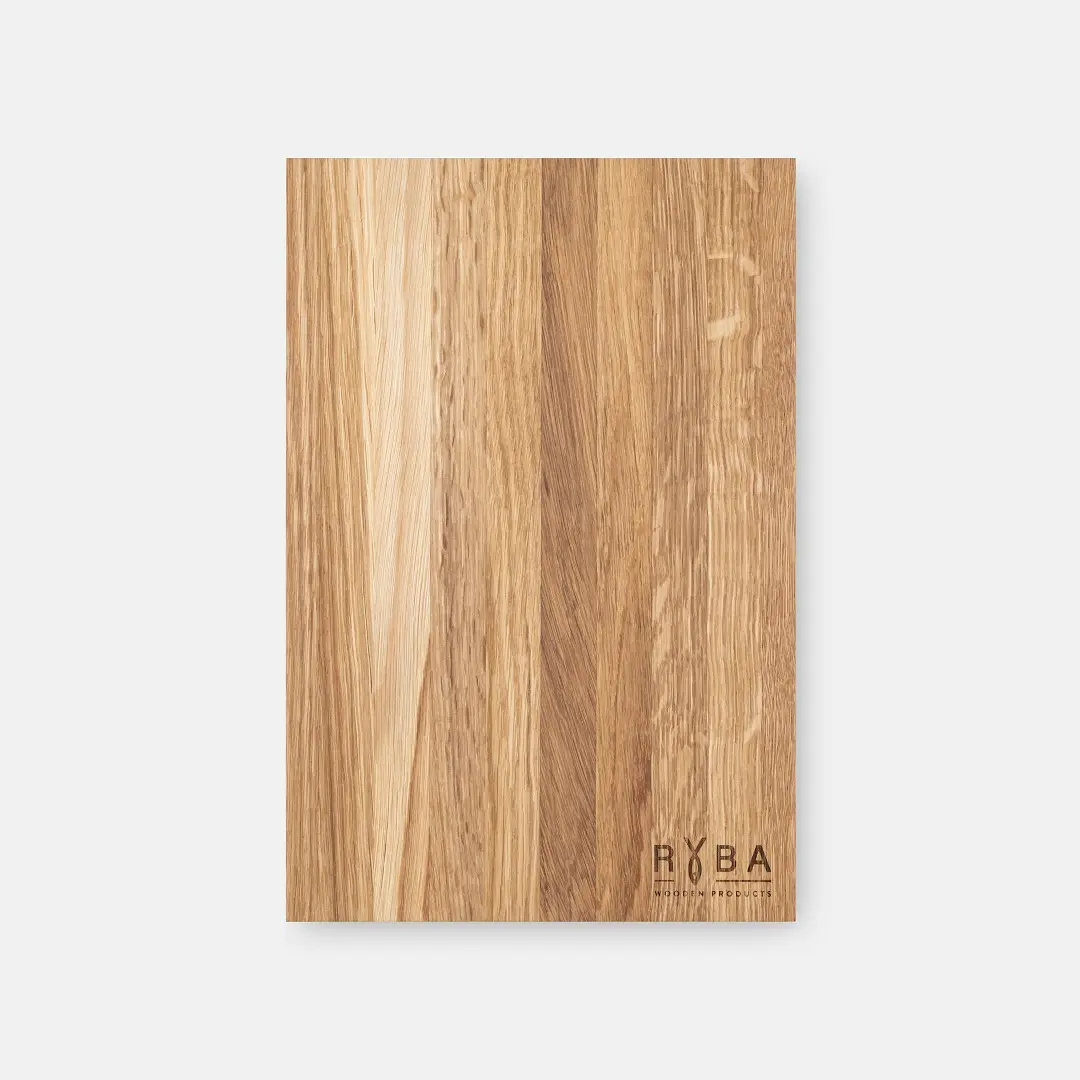

Thermoash

(

Fraxinus

)

Thermo-ash is ash wood that has undergone a thermal treatment process, which significantly improves its durability and stability. The raw material comes from Poland and is processed in an environmentally friendly manner, without the use of chemicals.

Thermo-ash wood is characterized by a dark, uniform color – from warm shades of red to deep, dark brown. The grain pattern is moderate and rather symmetrical, giving the finished products an elegant and visually consistent appearance. Due to its dark color, thermo-ash is often compared to walnut, while being up to 40% cheaper.

In terms of usability, thermo-ash is characterized by very good durability. With proper maintenance, a cutting board made of this material can serve for many years. Additional advantages include a subtle, natural scent and a luxurious surface appearance.

The wood thermo-modification process

The wood thermo-modification process originated in Finland and is considered an environmentally friendly method of modifying wood. It involves prolonged heating of the wood at a temperature of 160 to 230°C, in the presence of steam, for 48–96 hours.

During this process, the natural sugars contained in the wood caramelize and its ability to absorb moisture is reduced. As a result, thermally modified wood gains increased resistance to the growth of fungi and bacteria, greater dimensional stability, and a characteristic darker color.

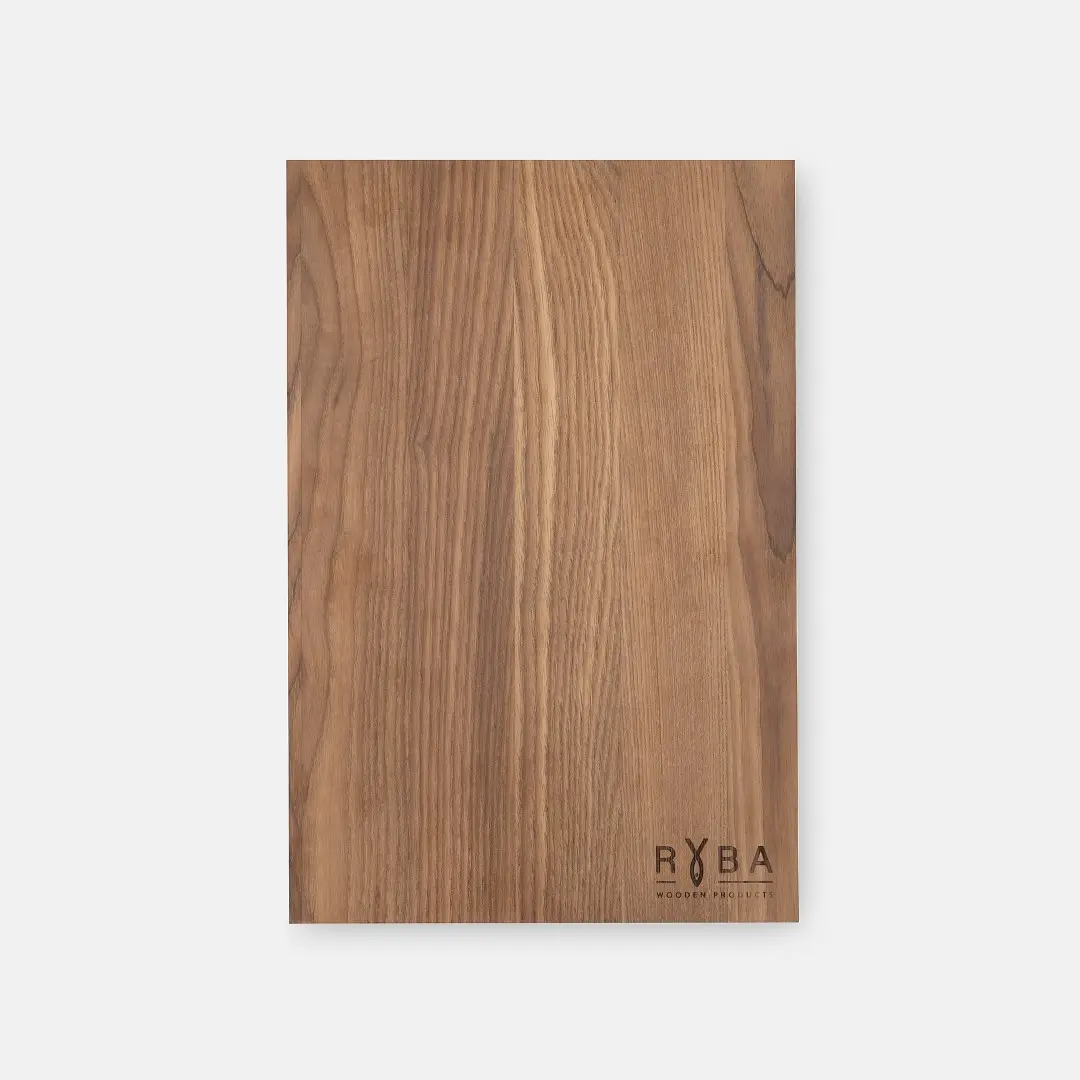

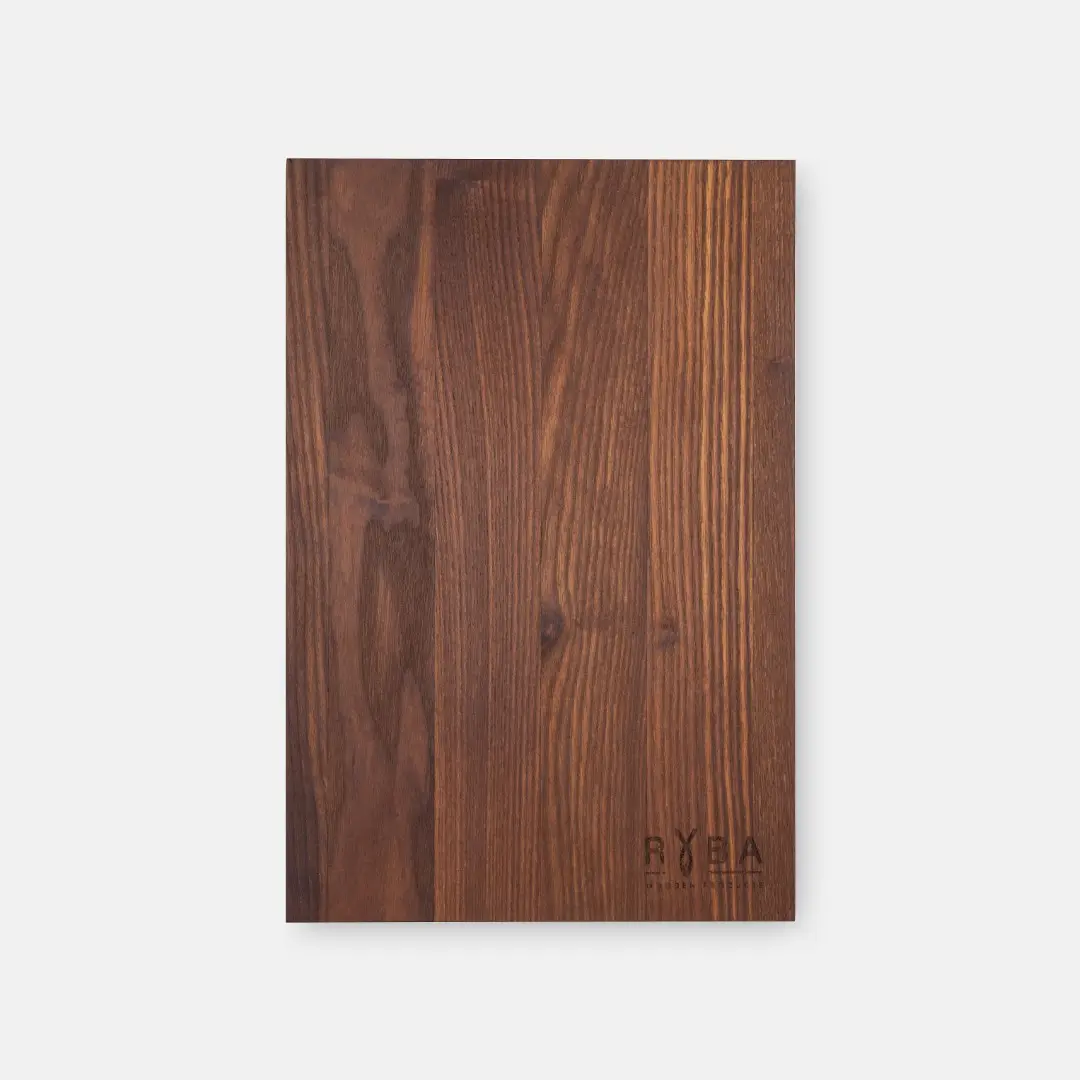

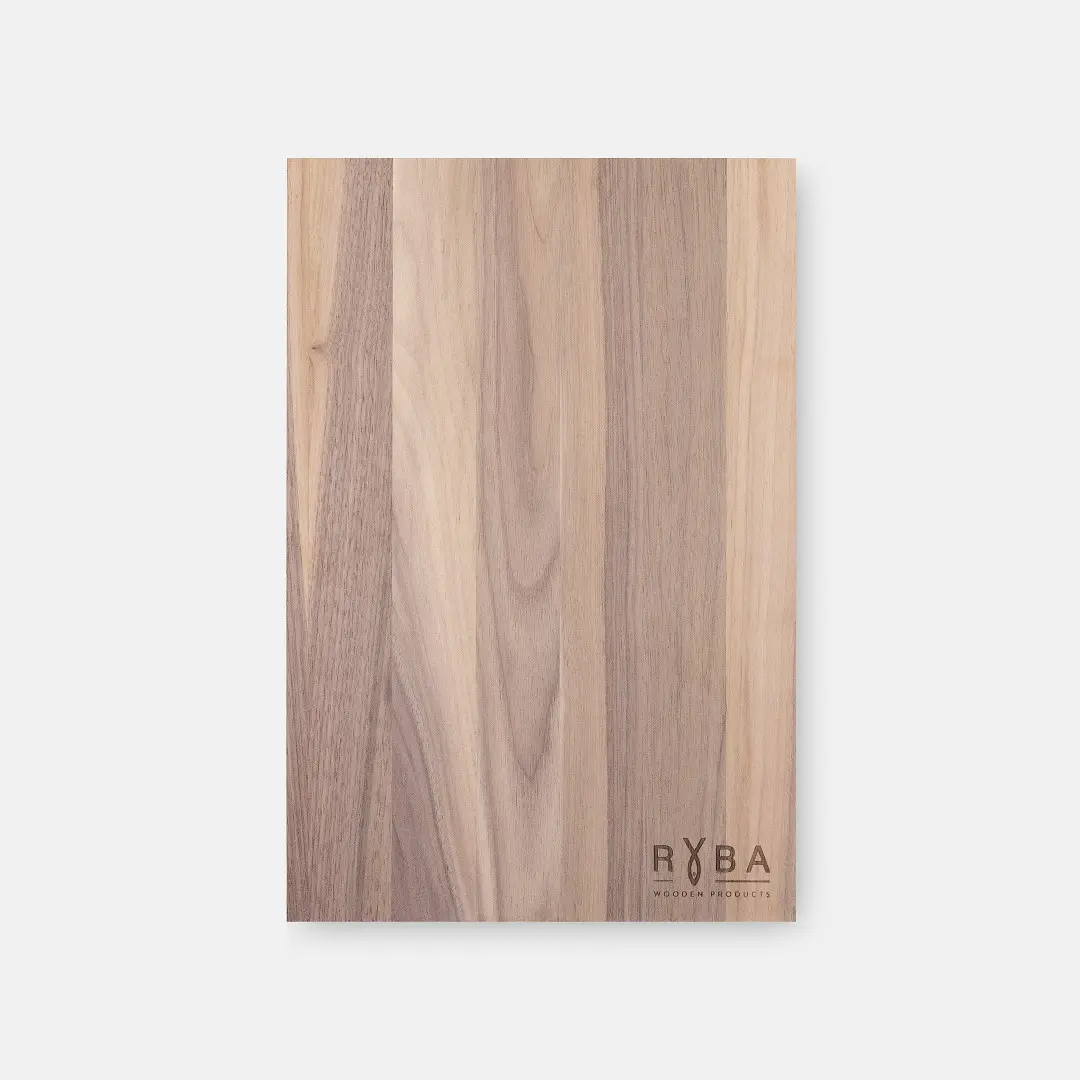

American Walnut

(

Fraxinus

)

American walnut is a wood native to North America, characterized by very good durability and high stability when properly maintained. In cutting boards, it ensures a long service life in domestic use.

The wood has a dark, uniform color ranging from red to dark brown tones and a distinct grain pattern.

Oiling American walnut boards strongly emphasizes its color. The difference is shown in the figures below.

Sapwood in American walnut occurs naturally in the outer part of the trunk (approx. 5-10% of the raw material). In production, approx. 10-15% of boards contain sapwood on one or both sides. Sapwood contrasts with heartwood and is not a material defect. more...

Pierwszy kontakt drewna orzechowego z wodą może spowodować szorstkość powierzchni. Efekt jest normalny i znika po kilku myciach more...

Origin of wood

The wood used in production comes from Polish forests*.

We purchase it:

- from State Forests in the form of logs (logs)

- in the form of sawn timber from sawmills that source it from Polish forests

(*) with the exception of American walnut, which is imported from the USA

EUDR

Yes. We only use wood from legal and controlled sources in our production, in accordance with the requirements of the EUDR.

We have documentation confirming the origin of the raw material and we apply due diligence procedures that enable the traceability of wood at every stage of the supply chain.

Do we have FSC certification?

Yes. As a company, we are FSC certified, which means that we are regularly audited by the independent certification body SGS in terms of the origin of raw materials, wood traceability, and compliance of processes with FSC requirements. We also have FSC-certified wood and use it in the fulfillment of orders at the customer's request.

Washing in a dishwasher

Woodeb cutting boards should not be washed in the dishwasher. High temperatures and detergents cause the boards to delaminate.